أرسل لنا رسالة

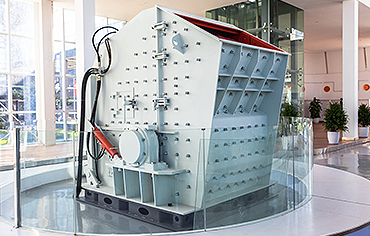

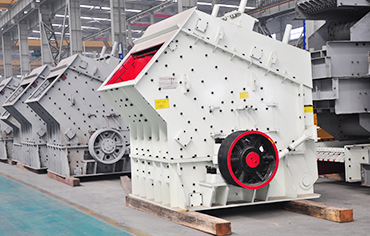

Impact crusher structure Figure area

Crusher &RQH&UXVKHU IOPscience

2022年2月18日 deploying moving units against a rigid unit or against another moving unit by the applied pressure, impact, and shearing or combine action on them. Crushers are

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4). A jaw crusher consists

Jaw CrusherJournal of Building EngineeringModelling and simulation of particle breakage in impact

2004年12月10日 In this , we present a phenomenological model that predicts the size distribution of the product issued from impact crushing in function of the rotor strike

作者: S. NikolovUnderstanding influence of crushers on shape

2017年9月30日 Usually, different types of crushers: vertical shaft impact crusher, horizontal shaft impact crusher, cone crusher and jaw crushers are used for production of

作者: Bharat Rajan, Dharamveer SinghGeometric analysis of cone crusher liner shape

2021年1月1日 The cross-sectional area and flow area variations with height allow the geometric constrictions that control flow and throughput to be quantified with, for

(PDF) A performance model for impact crushers

2002年10月1日 It can be applied to both hammer and vertical-axis impact crushers with the help of the corresponding estimations for the impact energy per unit mass.Here we propose classification and breakage...

Impact crusher structure, working principle and features

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single

Figure 1. Scheme of experimental impact crusher.

The horizontal impact crusher is mounted on a frame 15 and consists of a hopper 1 for the initial product with a volume of 1.5 l, a stator housing 4 with an outer diameter of 173

[PDF]Kony,c. 9, s. 4, 1040-1050, 2021 Konya Journal of

Then, rock materials above 70 mm are broken down by a jaw crusher whose dimensions are 1300 mm x 2400 mm. The CSS of the jaw crusher is 140 mm. The crushed particles

[PDF]Influence of Metallurgical Structure on the Behaviour of

2017年4月9日 vironment impact, both types parts in this study are the cone and blow bar which are mounted on the said crusher machines. BASIC PRINCIPLE OF CRUSHER

Optimization of key components of impact crusher based

2023年2月14日 By adjusting the major parameters and structures of the factors (rotor speed, angles of the first and second impact plates, shape of impact plate and blow bar material) influencing crushing effect, the orthogonal test with four three-level factors was conducted to find an optimal combination with the best crushing effect so as to optimize

Mathematical modeling of a vertical shaft impact crusher

2017年9月1日 Several mathematical models for the VSI crusher have been proposed in the last two decades or so. The Whiten crusher model, originally developed for cone crushers, has served as the basis of several approaches to model VSI crushers. In the present work, the Andersen/Awachie/Whiten model has been used as the basis for

Impact Crusher an overview ScienceDirect Topics

A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 4.4 (a)) and it is the most widely used in primary crushing stages ( Behera et al., 2014 ).

Numerical Simulation of a Single and Double-Rotor

2021年11月12日 The impact crusher design and the rendering of its simulated version are shown in Figure 1, with dimensions specified in Table 2. The results of the physical experiments that were conducted with a single impeller crusher have been reported in a recent stone [ 17 ].

Mathematical modeling of a vertical shaft impact crusher

2017年9月1日 Vertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the construction industry, not only due to their...

Geometric analysis of cone crusher liner shape

2021年1月1日 The mantle/cone is the central structure in the lower half of the figure (coloured green). The concave is the surrounding outer structure (coloured brown) in the middle of the figure. Variation with height in the crusher of a) the area ratio W, and b) the flow area for CSS of 8.3 mm and an eccentric angle of 1.73 degrees. (LRR and ARR

[PDF]DESIGN AND ANALYSIS OF IMPACT CRUSHERS CORE

2021年8月12日 Roll- Under the guidance of Prof. N.Kavi Department of Mechanical Engineering National Institute of Technology Rourkela 2007 CERTIFICATE This is to certify that the project work entitled “Design and Analysis of Impact Crushers” by Sidhartha Patnaik and Biswajit Pattnaik has been carried out under my supervision in

Working principle of impact crusher

2020年5月14日 The process of material crusher impact crusher ( see Figure Impact Crusher 2 ). impact-crusher-2. Impact Crusher is a broken machine which use of impact energy to crushing material. When the

impact crusher working principle Henan Deya Machinery

2021年9月2日 1. Impact crusher structure; 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body.

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton/hr.

Optimization of key components of impact crusher based

2023年2月14日 Inspired by the bionic wear-resistant structure, the shape and parameters of an impact crusher chamber are optimized. Taking both crusher strength and crushing effect into consideration and using discrete element method, the parameters of the impact crusher chamber were properly optimized.

Mathematical modeling of a vertical shaft impact crusher

2017年9月1日 Vertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the construction industry, not only due to their good energy efficiency but also to their ability to generate more isometric and tougher particles, which is highly desirable in cement mortars and conc...

Numerical Simulation of a Single and Double-Rotor

2021年11月12日 However, the energy associated with the double impeller impact crusher is much higher and energy intensification, rather than energy efficiency, is the main gain of the double impeller design. Figure 10. Highlighted area showing cross-section of the crusher sampled to obtain average speeds. Figure 11. The distribution of particle speeds

Understanding influence of crushers on shape

2017年9月30日 1. Introduction Aggregates of different sizes are used in significant proportion for production of asphalt mixes. In asphalt mixes, coarse aggregates provide major load distribution network, while fine aggregates fill the voids among coarse aggregates skeleton, and asphalt binder provides glue action for aggregates to form a monolithic

Geometric analysis of cone crusher liner shape

2021年1月1日 For aggregate operation, Onnela et al. (2012) identified key factors for design and operation as “Head angle and diameter, gyration point, shaft speed, eccentricity, stroke length and inclination and design of the crusher cavity”. With the exception of shaft speed, these are all geometric aspects of a cone crusher design.

[PDF]DESIGN AND ANALYSIS OF IMPACT CRUSHERS CORE

2021年8月12日 Roll- Under the guidance of Prof. N.Kavi Department of Mechanical Engineering National Institute of Technology Rourkela 2007 CERTIFICATE This is to certify that the project work entitled “Design and Analysis of Impact Crushers” by Sidhartha Patnaik and Biswajit Pattnaik has been carried out under my supervision in

(PDF) COMPARISON OF SECONDARY CRUSHING

2020年9月20日 Schematic illustration of the crushers considered in this study a) Cone crusher b) Horizontal shaft impact (HSI) crusher (Dr: rotor diameter, Mo: mainframe opening of the crusher chamber, CSS

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton/hr.

[PDF]DYNAMICAL MODELING OF IMPACT CRUSHER’S ROTOR

2022年4月5日 The computed values of the impact force, impact impulse and time of impact are given in table 1. Accounts for four levels of the peripheral velocity are done. Dynamical model of impact crusher’s rotor must be solved for all four levels of the peripheral velocity. The dynamical model of the rotor is shown of figure 1.

impact crusher working principle Henan Deya Machinery

2021年9月2日 1. Impact crusher structure; 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body.